What are the recommended applications for Invisible Speakers?

Invisible speakers are most commonly specified in design oriented applications where visible speaker grilles would detract from the design aesthetic of the space. Design critical living spaces such as Living rooms, dining rooms, master bedrooms or upscale commercial spaces are common applications for Invisible Speakers.

Driver protection

How can I be confident that these speakers will not be damaged by being played too loud or driven with too much power?

The drivers in most of the Invisible Speaker brands are protected by independent self-resetting poly switches. Once the maximum volume limit is reached the poly switches engage and protect the drivers from damage.

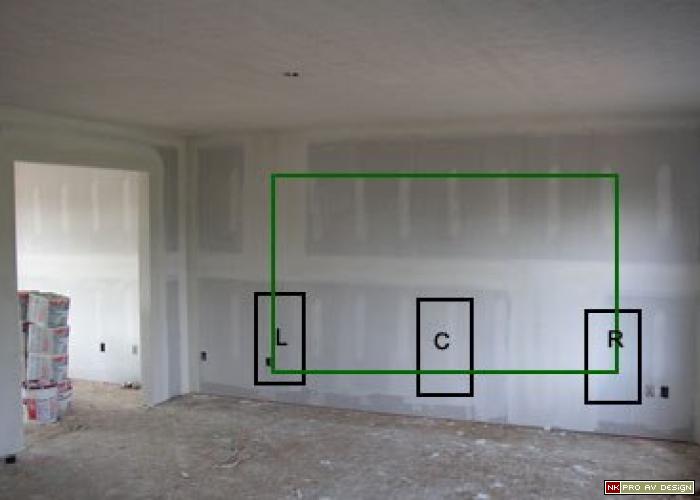

Installation & Finishing

What is the proper speaker positioning relative to the wall or ceiling surface?

To achieve the best audio quality the front surface of the speaker must be flush with the wall or ceiling surface. This is done to minimize the amount of topping compound that is used to hide the speakers. The Invisible Series speakers can be used with up to 1/8” (3mm) of topping compound if the installation requires it but the highest audio performance will be achieved when the topping compound is kept to a minimum. If the speaker is initially set too deep relative to the wall or ceiling surface, too much topping compound will be required to cover the speaker surface resulting in potentially poor audio quality. Most Invisible Series speakers come with a complete set of easy to identify multiple depth shims. These shims are used to position the speaker flush to the wall or ceiling.

What topping compounds should be used with Invisible Series Speakers?

Any topping compound that is suitable for drywall will yield excellent results with the Invisible Series Speakers. The most common topping compounds are setting and non setting joint compounds. Setting type joint compounds contain chemicals that speed up the drying process, these are commonly called hot mud.

Tested and Recommended topping compounds:

USG Sheetrock Brand Durabond

USG Sheetrock Brand Easy Sand

USG Sheetrock Brand All Purpose Joint Compound British Gypsum Easi-fill

Nylon mesh tape should be used to cover the joint between the speakers and the wall or ceiling surface. The topping compound will then be used to finish over the surface of the speaker.

What materials can be used to finish Invisible Speakers?

The materials must be pliable, elastic materials. Cement types of plasters or stuccos are too rigid and will not yield good audio quality. Paper backed wood veneer, acrylic and lime based Venetian plasters, thin wall papers and any semi-elastic wall topping compound will yield satisfactory finish results and good audio quality.

What keeps the surrounding drywall from cracking after extended play?

Most of the invisible speakers are constructed on an extremely ridged extruded aluminum frame. This frame prevents any of the speaker diaphragms movement from extending beyond the edge of the speaker. Additionally, the moving part of the diaphragm is set back 1” or 25mm from the edge of the speaker. Invisible Speakers have been used for decades in residential and commercial applications without ever experiencing any problems occurring in the wall surfaces.

How do I prevent the sound from the rear of the speaker from radiating into adjacent rooms?

Metal acoustic enclosures are available as an accessory for invisible speakers. The acoustic enclosure reduced the output from the back of the speaker by approximately 20dB.

Dispersion

Do Invisible Speakers offer the same coverage as conventional speakers?

Due to their design most of the invisible speakers have 150~170 degrees of hemispherical dispersion up to 10kHz, giving them much broader dispersion than conventional speakers. This means in distributed audio systems fewer Invisible speakers are needed to provide even coverage to a given area.